How EcoCOOL Works

The compressors that run our air conditioning and refrigeration systems suffer from an inherent condition that steadily reduces their efficiency over time. That condition is called oil fouling. The American Society of Heating Refrigeration and Air Conditioning Engineers (ASHRAE) recognizes this problem and the impacts that oil fouling can have on reducing the efficiency of equipment. It doesn’t cool like it should, it works harder, and costs more to operate.

Oil fouling is an insulating barrier of compressor oil that builds up on the inside surface of the evaporator coil tubing. Because refrigerants conduct the most efficient heat exchange only when they are in direct contact with the metal surface of the coil tubing, insulating barriers of any kind reduce efficiency significantly. To restore lost efficiency oil fouling must be removed.

EcoCOOL removes oil fouling and prevents it from reoccurring more effectively than any solution available today. But to further improve and protect the performance and efficiency of air conditioning and refrigeration systems, EcoCOOL does much more. EcoCOOL is a synthetic catalyst which has been engineered specifically to restore cooling systems to optimum

efficiency and maintain that efficiency for the life of the equipment.

A synthetic catalyst does not change the composition of compressor oils or refrigerants. It causes a reaction by its presence, after the reaction has taken place the catalyst is recycled and continues to enhance the performance of the system indefinitely. EcoCOOL is a scientific balance of three complementary components. Catalyst one, catalyst two, and an advanced lubricity agent.

Here’s how they work.

Catalyst 1

This catalyst removes oil fouling and stops it from ever occurring again. Once EcoCOOL has been installed, equipment will never lose efficiency due to oil fouling again. Catalyst 1 is a development of surface science. It actually breaks down the van der Waals forces or surface tension that causes compressor oil molecules to adhere to the inner surfaces of the evaporator and condenser coil tubing. This catalytic action creates clean metal surfaces within the inner walls of the coil tubing, enabling optimum heat exchange. The compressor oil that caused the oil fouling is released and continues to circulate within the system. Its original composition is completely unchanged.

Catalyst 2

The second catalyst contributes additional energy efficiency through improving the performance of the refrigerant. Catalyst 2 causes the refrigerant to carry more heat exchange. This catalytic action takes place within a fraction of a second in the pressure shock wave generated in the expansion valve. The effect is an increase in the mass of the refrigerant molecules. The increased mass and surface area increases the BTU’s of heat the refrigerant can move. Because this action is also caused by a synthetic catalyst the chemical composition of the refrigerant is not changed and the catalyst is recycled.

The Lubricity Agent

Having removed oil fouling and improved refrigerant efficiency, the third component of EcoCOOL is the lubricity agent, designed to specifically improve lubrication, reduce mechanical wear, and achieve smoother quieter operation. Lubricity agents greatly increase lubrication so that bearing surfaces show little wear over the lifetime of equipment. EcoCOOL’s lubricity agent has been independently evaluated by Intertek, one of the world’s leading laboratories.

The test using industry protocols concluded that the EcoCOOL lubricity agent improved compressor oil lubricating by 54 percent.

EcoCOOL – increasing energy efficiency through real science.

How We Track Energy Savings & Increased Operational Efficiency

Tracking changes in operational efficiency of air conditioning, refrigeration, and heat pump systems requires consideration of a number of factors, such as:

- Consistency in temperature set points or consistent changes to set points

- Hours of operation. (The amount time the system calls for cooling, which can be normalized)

- Fluctuations in external heat load, or environmental temperatures, which vary from day to day, month to month and/or year to year.

- Cooling degree days are used to determine how one day is hotter or cooler than the next

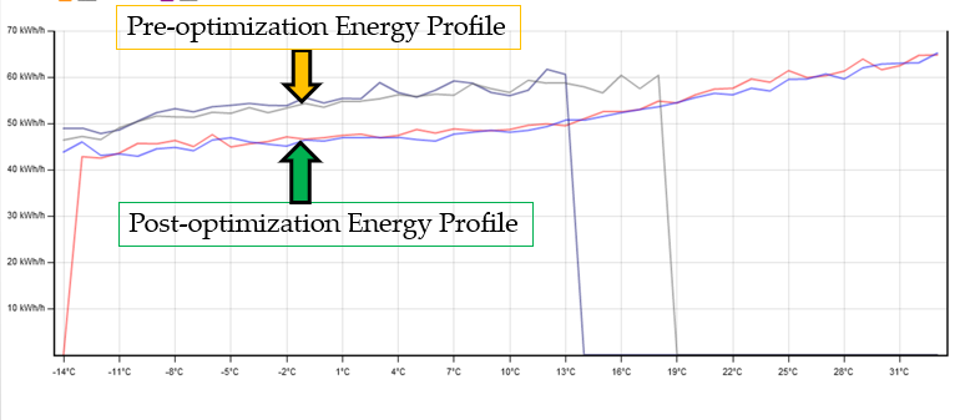

In order to compare apples to apples, we need to first be able to establish an average baseline that can show the changes in the energy consumption that has a direct correlation to the changes in external heat load or changes in energy use. Which in result, is able to determine the changes in energy usage based on the fluctuations in energy consumption.

A base line is established by remotely monitor energy consumption for a minimum period of (X) days. While the energy consumption data is being collected, the software simultaneously pulls temperature data from the nearest National Weather Service monitoring station.

- Weather and Utility readings are taken simultaneously every 10 seconds

- The data is used to create an algorithm.

- This algorithm is a calculation of energy use based on seasonal temperature.

Once the pre-installation base line is established we can now use that algorithm to determine energy consumption at any given seasonal temperature.

After installation, and an estimated 15-day reaction period, the collected information gives the ability to compare the baseline energy algorithm to actual energy consumption, with the difference representing the increase in efficiency through verifying the decrease in energy consumption.

This decrease in energy consumption is a direct representation to the savings on your electric bill.